Overview

Pager Power has been undertaking glint and glare assessments for solar developments for almost 10 years. During this time, we have heard and read a variety of misconceptions about solar panels and glint and glare; therefore we wanted to produce a brief article detailing and explaining some of the common misconceptions we encounter.

Misconception 1: ‘Solar panels do not produce glare due to their anti-reflective coating‘

This is probably the most common misconception we come across when it comes to comments regarding solar reflections from solar panels. It is often said that ‘solar panels are designed to absorb sunlight’ and that ’solar panels have an anti-reflective coating which eliminates glint and glare effects’. From a physics perspective, no coating will ever eliminate reflections. If this were the case, you wouldn’t be able to see the solar panels as the light would never reach your eyes.

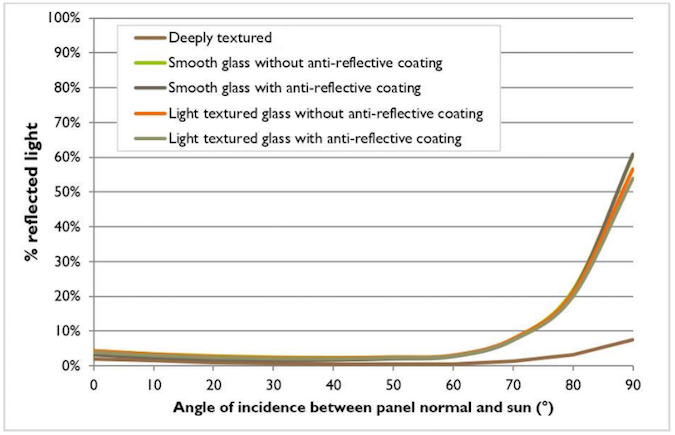

Of course, the key issue is specular reflections when it comes to glare. Whilst many solar panels have anti-reflective coatings that will reduce the intensity of any specular reflection, it is shown in Figure 1 [1] below that the majority of coatings only make marginal differences o the percentage of sunlight reflected. This is because most solar panels have a shiny surface or glass panel to protect it, whilst still letting light through. Shiny surfaces, such as glass, are capable of producing specular solar reflections and this is the main cause of glint and glare effects.

Figure 1: Reflectance profiles of typical PV module materials.

The graph also shows how the percentage of reflected light changes with the angle of incidence from the four common solar panel surface types. The graph shows a rather surprising result, in that the percentage of reflected light changes marginally depending on the surface type modelled. Only solar panels that are ‘deeply textured’ reflect relatively low levels of incoming light across all angles of incidence. It is understood however that solar panels with a deeply textured surface are often not viable for an actual PV development due to cost and the current availability of the technology.

At most, manufacturers typically claim to produce solar panels with an ‘anti-reflective coating’. Only in borderline circumstances may the percentage of reflected light be reduced through the implementation of ‘rougher’ panel surfaces such that the intensity of reflectance reaches acceptable levels. i.e. trying to eliminate ‘yellow’ glare towards aviation receptors. See our guidance document for more information in this area.

Misconception 2: ‘Having views of the panels means you will experience glint and glare’

Just because you can see the solar panels, it doesn’t mean you will necessarily experience glare from the solar panels. This is a common misconception mostly observed within objections to a development or from media articles surrounding a project. The 3D location relative to the solar panels, their specific layout (azimuth and elevation angle), as well as the pathway of the Sun across the sky at that location will determine where a solar reflection is possible. The size of the solar panel area as a whole will then influence the duration of any solar reflection at a location. Therefore, there are only specific locations where glint and glare effects can occur.

It is true however that if you cannot see the face of the solar panel, then no glint and glare effects are possible.

Misconception 3: ‘South-facing panels produce reflections towards the south’

Generally speaking, south-facing panels in the northern hemisphere, and north-facing panels in the southern hemisphere do not produce solar reflections directly south towards ground-based receptors when positioned at typical elevation angles (10-35 degrees). In most cases, solar reflections are cast between northeast and southeast, and southwest and northwest of the panel area.

Misconception 4: ‘Tracking solar panels eliminate glare’

This all depends on the receptors and the tracking panel characteristic. It is possible to eliminate glare effects at ground level by changing the rest angle of the panels (assuming a typical single axis tracker system), however this requires detailed modelling (which is site specific) because it is dependent on the relative 3D location of the ground-based receptors to the solar panel area. For aviation receptors however, solar reflections may still be produced skyward during the tracking process. In summary, whilst in most cases tracking systems can be programmed to reduce glare, this isn’t inherently the case.

Misconception 5: ‘I don’t need to do a glint and glare assessment for my development’

It is true that a planning authority or stakeholder may not request a glint and glare assessment however, we are more and more often receiving last-minute inquiries for glint and glare assessment regarding projects that are already in planning and require quick turnaround times. It is therefore worthwhile investigating the requirement for a glint and glare assessment to avoid unnecessary time and financial pressures late on in the project timeline.

About Pager Power

Pager Power has undertaken over 600 glint and glare assessments around the world including Europe, India, Australia, and South Africa. For more information about what we do, please get in touch.

References

[1]Yellowhair, J. and C.K. Ho. Assessment of Photovoltaic Surface Texturing on Transmittance Effects and Glint/Glare Impacts. ASME 2015 9th International Conference on Energy Sustainability collocated with the ASME 2015 Power Conference, the ASME 2015 13th International Conference on Fuel Cell Science, Engineering and Technology, and the ASME 2015 Nuclear Forum. 2015. American Society of Mechanical Engineers.

Thumbnail image accreditation: Michael Wilson (November 2019) from Unsplash.com. Last accessed on March 28th 2022. Available at: https://unsplash.com/photos/jld4MmOc4Uk