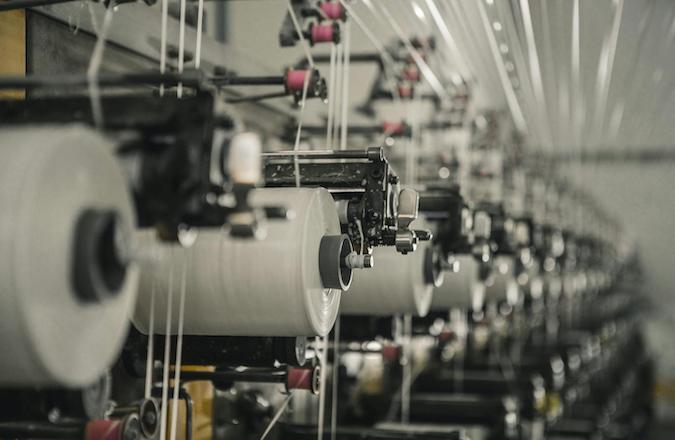

The textile industry, one of the world’s largest and most resource-intensive sectors, is undergoing a notable transformation. In response to rising concerns about climate change and environmental deterioration, textile manufacturers are increasingly turning to renewable energy sources to decrease their carbon footprint and create a more sustainable supply chain.

Why Energy Matters in Textiles

Textile production uses energy at nearly every stage, from growing raw materials like cotton to spinning, weaving, dyeing, finishing, and transporting final products. Usually, this energy comes mainly from fossil fuels, which are limited and significant sources of global greenhouse gas emissions, as touched upon in the article on the cotton industry here.

The move to renewable energy, such as solar, wind, biomass, and geothermal, is more than a passing trend. It’s a vital shift towards environmental accountability and long-term energy security for the sector [1].

Figure 1: Textile Factory in Indonesia [2]

Renewable Technologies in Action

- Solar Power – Solar energy is widely used in the textile industry, particularly through photovoltaic (PV) panels installed on factory rooftops. These systems provide clean electricity for machinery, lighting, and water heating in dyeing and washing operations. Advanced solar thermal systems can also supply high temperatures for many textile processes.

- Wind Energy – Textile facilities in windy regions are increasingly partnering with off-site wind farms through Power Purchase Agreements (PPAs) or investing in on-site wind turbines. Wind energy offers a consistent and scalable power source, primarily when supported by battery storage systems to manage supply variability.

- Biomass and Combined Heat and Power (CHP) – Biomass energy, produced from agricultural waste or sustainably sourced wood, can run CHP systems that generate electricity and heat. These systems are beneficial for processes like fabric finishing, which need large amounts of steam and thermal energy [1].

Energy Efficiency and Sustainable Materials

Implementing renewable energy is most effective when combined with energy-saving measures. These include upgrading to energy-efficient machinery, optimising dyeing temperatures, and improving building insulation to reduce heating and cooling needs.

In addition, using sustainable materials, such as organic cotton, hemp, or recycled polyester, helps lower the energy production of textile products.

Beyond Power: The Next Generation of Smart Textiles

Looking further into the future, the industry is researching energy harvesting textiles. These innovative fabrics, embedded with flexible solar cells, piezoelectric fibres, or thermoelectric elements, can generate electricity from sunlight, body movement, or temperature differences.

Such textiles could transform clothing and home furnishings into active energy sources, potentially feeding energy into buildings or devices. Though still in development, these technologies represent a bold reimagining of what textiles can do in a low-carbon future [3].

A Necessary Shift for a Sustainable Industry

The textile industry faces a crucial challenge. As climate concerns increase and regulations become tighter, companies must find ways to expand without harming the environment. Embracing renewable energy, energy efficiency, and sustainable materials is vital to that journey.

By investing in clean technologies and innovative production models, the textile sector can dramatically reduce its environmental impact and help build a more sustainable, resilient global economy.

About Pager Power

Pager Power undertakes technical assessments for developers of renewable energy projects and tall buildings worldwide. For more information about what we do, please get in touch.

References:

[1] Energy Sustainability Directory – Renewable Energy in Textiles. Accessed on 08/07/25. Available at: https://energy.sustainability-directory.com/term/renewable-energy-in-textiles/

[2] Kevin Limbri – Textile Factory, Indonesia 2023. Accessed on 31/07/25. Available at: https://unsplash.com/photos/a-row-of-machines-that-are-next-to-each-other-mBXQCNKbq7E

[3] Fibre2Fashion – Energy Harvesting Smart Textiles. Accessed on 11/08/25. Available at: https://www.fibre2fashion.com/industry-article/10427/energy-harvesting-smart-textiles-a-new-era-of-self-powered-fashion-and-home-textiles