The fashion industry is renowned for its creativity but has a serious downside: it is one of the most significant contributors to environmental degradation today.

Have you ever checked the labels of your favourite clothing? Polyester, nylon, and acrylic might appear harmless, but they release microscopic plastic fibres into our waterways and air with every wash and wear.

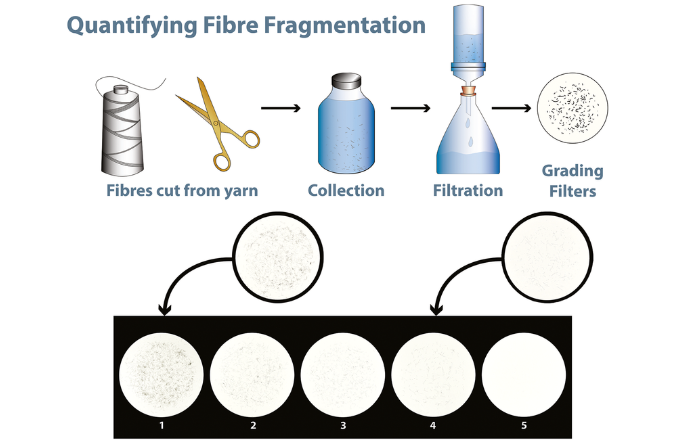

However, there’s a ray of hope. Researchers at Heriot-Watt University in Scotland have introduced a groundbreaking grading system designed to combat microplastic pollution. This innovative approach features the world’s first visual fibre fragmentation scale, allowing for a quick assessment of the volume of fibres released from various clothing materials.

After four years of rigorous study, the team developed a five-point scale: grade one indicates the highest volume of shed fibres, while grade five signifies the least. This method is swift and more cost-effective compared to existing techniques like those employed by the International Organisation for Standardisation (ISO). The tide may be turning in the fashion industry’s battle against microplastic waste [1].

Figure 1: Man and Woman Holding Clear Plastic [2].

How Does ISO Currently Evaluate Microplastics in Textiles?

In September 2023, ISO introduced ISO 4484-2, which aims to provide information about the nature, numerical concentration, surface area, and estimated mass of microplastics emitted by the textile industry and subsequently found in various matrices.

The initial step involves pre-treating the test specimen to eliminate any inorganic and organic components that may interfere with the identification of microplastics. Following this treatment, the specimen is placed on a suitable filter, which allows for subsequent microscopic analysis methods, such as Micro-FTIR or Micro-Raman. Raman tends to be the preferred choice for identifying smaller microplastics, including nano plastics, as it can detect particles much smaller than FTIR (Raman can detect particles down to 1µm).

These methods assess both the quality and quantity of microplastics. The analysis provides information on the number of microplastic particles, their morphological characteristics, size, and dimensional distribution, as well as the polymers’ fibre content and chemical origin. Results are reported regarding estimated surface area and mass of microplastics per sample [3].

How Does Heriot Watt University’s New Grading System Improve on This?

The recommended gravimetric analysis of the textile microplastic results takes over 8 hours per specimen batch. In addition to specimen preparation, testing and effluent filtration, analysing test results is prohibitively time-consuming and expensive for many brands [4].

The university’s new five-point grading system provides a much more speedy and cost-effective process. Dr Lisa Macintyre, Associate Professor and Global Programme Director at Heriot Watt University said:

“The microplastics problem is massive. Fashion and textiles is one of the biggest sources of secondary microplastics in the environment with fragments of plastic fibres, like polyester and nylon, being shed from clothing.

“There are fibre fragments absolutely everywhere, from icebergs to the deepest ocean to human lungs and our food, they’re in everything.

“Visual scales are already used in the fashion industry to measure how much bobbling a material may suffer on its surface for example or, perhaps the most well-known is the grey scale, which measures colour fading or staining, but there was no such tool for fibre shedding.

“This project aims to change that and allow manufacturers to not only make better choices in production but also to communicate to their customers in a very simple and straightforward way, the typical amount of fibres shed from a garment.” [5].

Figure 2: Quantifying Fibre Fragmentation Diagram [4]

“The ultimate aim is for manufacturers to choose materials that are going to have the least impact on our environment but also allow consumers to make an informed decision when they buy their clothing.” [5].

Conclusions

The textile industry has not yet accepted the new grading system. If the industry adopts it, the fibre fragmentation scale could be included on clothing labels, much like how many UK food manufacturers display calorie information on their packaging.

As Dr Macintyre added on her part: “The next stage for us is to try and get some kind of industry agreement. Currently, we don’t have an ‘acceptable fragmentation’ rate for clothing but that’s not unusual.”

“The environment is an important issue, and we’d want to get key industry leaders and policymakers to sit down and start agreeing standards, perhaps even legislating against high shedding materials,” she concluded.

Informative information on the findings of the study has been featured in a new paper, entitled, ‘Low-cost, high-throughput quantification of microplastics released from textile wash tests: Introducing the fibre fragmentation scale’, published in the Cambridge Prisms: Plastics journal on the 19th of November which can be found here [1].

About Pager Power

Pager Power undertakes technical assessments for developers of renewable energy projects and tall buildings worldwide. For more information about what we do, please get in touch.

References

[1] Fashion United – Heriot-Watt University researchers developed a system to combat microplastic pollution in fashion. Accessed on 02/12/24. Available at: https://fashionunited.uk/news/fashion/heriot-watt-university-researchers-develop-system-to-combat-microplastic-pollution-in-fashion/2024112078673

[2] Cottonbro Studio – Man and Woman Holding Clear Plastic. Accessed on 16/12/24. Available at: https://www.pexels.com/photo/man-and-woman-holding-clear-plastic-10037673/

[3] SGS – ISO Launches New Test Method for Conducting a Qualitative and Quantitative Analytical Evaluation of Microplastics. Accessed on 13/13/24. Available at: https://www.sgs.com/en/news/2023/11/safeguards-15623-iso-launches-new-test-method-for-conducting-analytical-evaluation-of-microplastics

[4] Cambridge University Press – Plastics. Accessed on 16/12/24. Available at: https://www.cambridge.org/core/journals/cambridge-prisms-plastics/article/lowcost-highthroughput-quantification-of-microplastics-released-from-textile-wash-tests-introducing-the-fibre-fragmentation-scale/43BB7CD7E22ACF3A2E7E9C8050E5DF41

[5] Heriot Watt University – World’s first visual grading system developed to combat microplastic fashion pollution. Accessed on 16/12/24. Available at: https://www.hw.ac.uk/news/2024/worlds-first-visual-grading-system-developed-to-combat-microplastic-fashion-pollution